Magnetic Separators – OVE/OVP

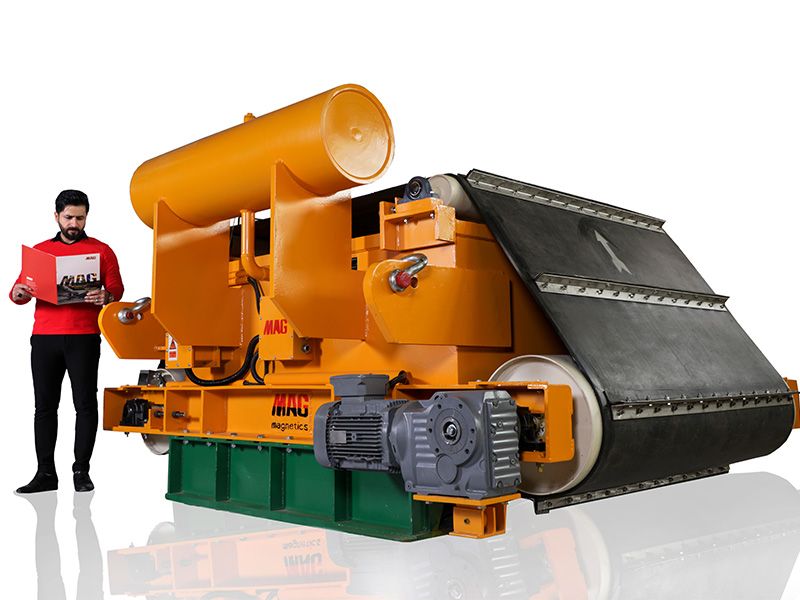

Over Belt Magnetic Separators: Electrical (OVE) / Permanent (OVP)

For decades, MAG Group’s over belt magnetic separators have been extensively used in various industries. These machines used for picking up and removing tramp iron objects from the bulk materials such as coal, stone, fertilizers, slag, gypsum, ores and similar in order to protect crushers, pulverisers, mills, conveyor belts and other valuable equipment in processing plants against too much wear and damage.

OVE/OVP self-cleaning over belt magnet series used when there are substantial quantities of tramp irons, which are contained in the conveyor burden or where access to the magnet for manual cleaning is difficult. The separator attracts tramp irons and carries them out of the magnetic field and ejects by the discharge belt running around the magnet.

MAG Group’s self-cleaning over belt magnets consist of magnetic box, supporting structure for the discharging belt with drive and tail drums and two additional idlers are mounted on the suitable self- aligning bearings. A suitable geared motor is used to drive the discharging belt. For re-tightening the discharging belt, the fixed axle of the tail drum is fitted with a device for tensioning. Suspension lugs, set of turnbuckles and suspension wire ropes are supplied.

Important factors, which are absolutely essential for selection of over belt magnetic separators:

-

Material size, type and density

-

Shap and minimum size of the tramp irons

-

Maximum material lump size

-

Percentage of tramp iron in material

-

Conveyor belt / Chute width

-

Bulk material capacity (t/hr or m3/hr)

-

Detail of machines or equipment to be protected

-

Conveyor belt speed

-

Angle trough idlers

-

Head pulley diameter and material (at in-line installation)

-

Ambient temperature

-

Available power supply AC

MAG Group offers a wide ranges of standard electrical (OVE series) or permanent (OVP series) over belt magnetic separators which are suitable for belt width up to 2500mm and operating heights up to 800mm. Electrical over belt magnets could be chosen as “air cooled” or “oil cooled” magnet. The oil cooled magnets are generally shorter in height and lighter in weight in compare to the equivalent air cooled magnets.

OVE electrical magnetic separators comply with the VDE 0580 standard. DC supply is required for excitation of the coils. The rectifiers and the three-phase current motors are figured for 415V/50Hz. The units can also be supplied for the other voltages as well as distinct frequencies. The magnets can be used in the normal operating conditions and the ambient temperature range -20 and +40 °C. Where extraordinary operating conditions prevail such as high ambient temperatures (over 40°C), high air humidity, chemically aggressive atmosphere, severe dust pollution, handling of wet and sticky material, very large tramp iron objects and hot materials, inevitably the special custom designed magnets are recommended.

OVP permanent magnets separators are powered by ceramic strontium ferrite magnets.

Advantage of the OVP magnets

-

No rectifier is required

-

No risk for burning-out the coil

-

No electrical cabling required for magnet

-

No power consumption

-

No operative cost

-

No maintenance

-

No failure

-

Easily mounted

-

Uniformly powerful

-

Affordable to purchase and operate

-

Even if power fails, magnet will hold

-

Moisture-resistant, anti-corrosion and flameproof

-

Fully stabilized and non-deteriorating